Material Flow Challenges in Precision Micro Injection Molding for Electronics

One of the primary hurdles in precision micro injection molding for electronics is ensuring consistent material flow into tiny cavities, often measuring less than 0.5mm in diameter. Traditional polymers struggle to fill these micro-features due to high viscosity, leading to incomplete filling, voids, or uneven wall thickness—critical flaws in components like micro-connectors or sensor housings. Our solution lies in optimizing both material selection and process parameters. We use low-viscosity, high-flow engineering resins specifically formulated for micro molding, which reduce resistance as they flow through narrow channels. Additionally, we employ advanced pressure profiling: ramping up injection pressure gradually to avoid turbulence while ensuring the material reaches every corner of the mold. By combining these strategies, our precision micro injection molding process achieves fill rates exceeding 99.5% for even the most intricate electronic components, eliminating defects that could compromise performance.

Dimensional Tolerance Control in Precision Micro Injection Molding for Electronics

Electronics demand dimensional tolerances as tight as ±0.001mm, a challenge that precision micro injection molding must overcome to ensure components fit and function correctly. Thermal expansion of both the mold and the material during cooling is a major culprit behind tolerance deviations, especially in micro-sized parts where even minor shifts are significant. To address this, we use ultra-precise mold materials with low thermal expansion coefficients, such as tool steel alloys, and equip molds with embedded temperature sensors to monitor and adjust cooling rates in real time. We also implement post-molding annealing processes to stabilize dimensions, reducing residual stresses that cause warping. Our quality control team uses laser interferometers and coordinate measuring machines (CMMs) to verify tolerances, ensuring every part meets the strict standards required for electronic assemblies. This level of control makes precision micro injection molding a reliable solution for high-precision electronic components.

Contamination Risks in Precision Micro Injection Molding for Electronics

Contamination—whether from particulate matter, moisture, or residual gases—poses a severe risk in precision micro injection molding for electronics, where even a 5-micron particle can short-circuit a microchip or block a fluidic channel. Traditional molding environments often struggle to maintain the cleanliness required for such sensitive applications. Our solution is a closed-loop manufacturing system housed in ISO 8 cleanrooms, where air filtration removes 99.9% of particles 0.5 microns and larger. We also pre-dry materials to less than 0.005% moisture content and use vacuum-assisted injection to eliminate trapped gases that could form bubbles. Every mold is cleaned with ultrasonic baths and plasma treatments between runs to remove residual material. By integrating these measures, our precision micro injection molding process reduces contamination rates to less than 0.01% per million parts, ensuring electronic components remain reliable in critical applications like medical devices and aerospace systems.

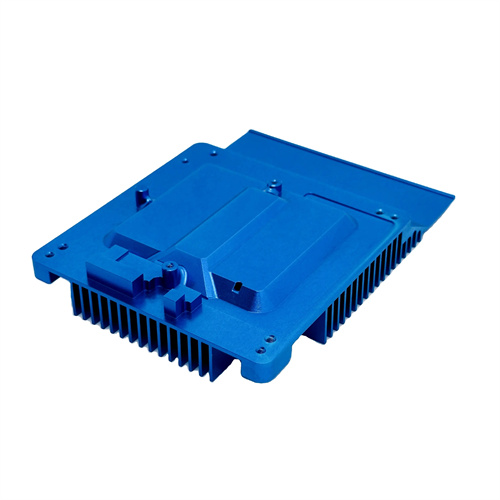

Tooling Complexity in Precision Micro Injection Molding for Electronics

Creating molds for precision micro injection molding of electronics is inherently complex, as they must replicate micro-features like fine pitch connectors, micro-vias, and textured surfaces with absolute accuracy. Traditional machining methods often lack the precision to create these features, leading to mold mismatch or incomplete part replication. We tackle this challenge with advanced mold-making technologies, including micro-electrical discharge machining (EDM) and laser ablation, which achieve feature resolutions down to 0.0005mm. We also use 3D printing for rapid prototyping of mold inserts, allowing us to test and refine designs before committing to full production tooling. Additionally, we incorporate conformal cooling channels into molds, which distribute temperature evenly across micro-features, preventing uneven curing and ensuring consistent part quality. These innovations in tooling make precision micro injection molding capable of producing the most complex electronic components with repeatable accuracy.

Process Repeatability in High-Volume Precision Micro Injection Molding for Electronics

Maintaining process repeatability is critical in high-volume precision micro injection molding for electronics, where batch-to-batch variations can disrupt assembly lines or cause product failures. Factors like material viscosity fluctuations, ambient temperature changes, and mold wear can all introduce inconsistencies, even in automated systems. Our solution is a smart manufacturing approach that combines IoT sensors with AI-driven process control. Sensors monitor over 50 variables in real time—including injection pressure, melt temperature, and cooling time—while machine learning algorithms adjust parameters dynamically to maintain optimal conditions. We also implement statistical process control (SPC) with Cpk values > 1.67, ensuring that 99.99% of parts fall within tolerance limits. Additionally, we use automated part inspection systems with machine vision to sort and reject out-of-spec parts, preventing them from entering the supply chain. This level of process control ensures that precision micro injection molding can deliver millions of identical electronic components with uncompromising quality.

Thermal Management Challenges in Precision Micro Injection Molding for Electronics

Many electronic components, such as power semiconductors and LED modules, require precision micro injection molding with materials that can withstand high temperatures, but balancing heat resistance with processability is a significant challenge. High-temperature resins like PEEK or LCP often have high melting points and low flow rates, making them difficult to inject into micro-cavities without degradation. We address this by optimizing both material formulations and molding parameters: we use glass-reinforced grades of high-temperature resins to improve flow while maintaining thermal stability, and we heat molds to temperatures up to 200°C to reduce material viscosity during injection. We also employ sequential valve gating to control material flow into micro-features, preventing overheating and ensuring uniform filling. The result is precision micro injection molded components that can operate at temperatures up to 260°C while retaining their micro-features and dimensional stability—critical for reliable performance in high-power electronic systems.