OUR CAPABILITIES

Custom Injection Molding

Custom injection molding services cater to specific client needs, offering tailored solutions for producing plastic parts. These services involve designing and manufacturing molds that meet unique specifications, ensuring high-quality, consistent production. Ideal for industries requiring specialized components, custom injection molding provides flexibility in material selection, design complexity, and production volume.

Injection Molding Parts

Injection molding parts are components produced through the injection molding process, where molten material is injected into a mold to form specific shapes. These parts are used across various industries, including medical, architecture, toys, household appliances, hardware tools, and consumer products. The process allows for high precision, repeatability, and the ability to use a wide range of materials, versatile for different applications.

Two Shot Injection Molding

Two shot injection molding combines two materials (such as hard rubber and soft rubber, different colors) into one through two injection molding processes, achieving functional integration and appearance optimization. The technological advantages include reducing assembly processes, improving product durability, and increasing design freedom. Typical applications include tool handles, multi hardness components.

High-Volume Injection Molding

High-volume injection molding is designed for mass production of plastic parts, ensuring efficiency and cost-effectiveness. This service is perfect for industries that require large quantities of identical components, such as LED lighting, electrical products, packaging and electronics. High-volume molding leverages advanced machinery and automation to maintain precision and consistency across millions of parts.

Precision Micro Injection Molding

Precision micro injection molding is used to manufacture extremely small and intricate parts with high accuracy. This process is essential for industries like medical devices, electronic products, electrical products and micro-optics, where components often have tight tolerances and complex geometries. Advanced machinery and precise control systems ensure that even the smallest details are reproduced consistently.

Liquid Silicone Rubber Injection Molding

Liquid silicone rubber (LSR) injection molding is a specialized process used to produce flexible, durable, and heat-resistant parts. LSR is ideal for applications requiring biocompatibility, such as medical devices, baby products, and automotive components. The process involves injecting liquid silicone into a mold, where it cures to form the final product, offering excellent elasticity to extreme temperatures.

Injection Molding Parts Manufacturer

We are a leading precision injection molding solution provider in China, focusing on providing high-quality and customized injection molding services to global customers. With 20 years of industry experience, it has developed into a comprehensive manufacturing enterprise integrating research and development, production, and sales, equipped with advanced equipment and professional teams, providing services covering automotive, medical, electronics, consumer goods, and other fields. We strictly follows the ISO 9001/13485 system and is equipped with CNC machining and coordinate measuring instruments to ensure that the entire process from prototype development to mass production is controllable. Cooperate with international material suppliers to support PP PE、ABS、PC、 Processing of multiple materials such as silicone, and providing value-added services such as surface treatment and assembly.

Our Molding Workshop

We always adhere to independent research and development and production of molds, equipped with a complete mold manufacturing workshop and advanced equipment, ensuring that the entire process from design to mass production is controllable. Our mold team is composed of experienced engineers who are skilled in optimizing designs based on customer product requirements. They use Moldflow analysis to predict molding defects and avoid risks in advance. The independently manufactured molds have a lifespan of over 500000 to 1 million cycles and support rapid repair and maintenance, effectively shortening customer product development cycles and reducing overall costs.

Core equipment and processes:

Electric Discharge Machining (EDM): Using high-precision EDM machines, it can achieve precise machining of complex cavities and microstructures, ensuring that the precision of mold details reaches the μ m level.

CNC Milling: Equipped with multiple high-speed CNC machining centers, it supports efficient milling of various materials to meet the rapid prototyping needs of high-precision molds.

Our Capabilities:

Customized injection molding: From mold design to material optimization, we provide precision machining throughout the entire process to ensure product accuracy and performance.

Large scale production: Automated production lines support an annual production capacity of over 10 million pieces, balancing efficiency and cost control.

Micro injection molding: Micro precision equipment achieves the processing of minimum 0.1mm micro parts, serving precision industries such as medical catheters and electronic components.

Double injection molding: Multi material co injection technology achieves integrated molding of complex structures, improving functional integration and appearance quality.

Liquid Silicone Injection Molding (LSR): Proficient in high elasticity, high temperature resistance, and biocompatibility silicone products, applied in fields such as medical and automotive seals.

OUR SERVICES

Product Design and Development

We provide full process services from product design to development. By collaborating with customers, we optimize product structure, material selection, and functional design to ensure that the product meets both functional requirements and is suitable for injection molding production. This service is particularly suitable for customers who need to develop new parts from scratch.

Quality Control and Testing Services

We will ensure that our products meet customer requirements through strict quality control processes. Common detection methods include size measurement (using calipers, coordinate measuring instruments, etc.). Strength testing (such as tensile, bending, impact testing). Visual inspection (such as surface smoothness and color consistency).

Customized Services

We can provide customized services based on customers' special needs, including customized mold design. Special material selection. Personalized surface treatment. Special packaging and logistics services. Customized services can help customers optimize product design, reduce costs, shorten design time, and more.

Products Showcase

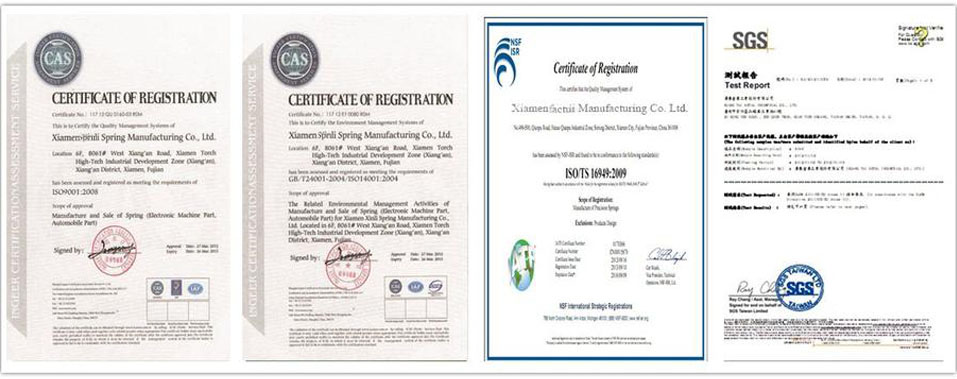

OUR CERTIFICATES