Technical Capability in Precision Micro Injection Molding

The foundation of a reliable precision micro injection molding supplier lies in their technical capability to consistently produce parts with ultra-tight tolerances—often as low as ±0.001mm. We prioritize evaluating a supplier’s equipment, including the precision of their injection molding machines (with clamping forces under 50 tons for micro parts) and their mold-making capabilities. Look for suppliers using micro-EDM and laser ablation for mold inserts, as these technologies ensure the replication of micro-features like 0.1mm holes or 0.05mm grooves. Additionally, assess their expertise in handling specialized materials, such as high-performance polymers (PEEK, LSR) and composites, which are critical for high-tolerance applications. A capable supplier should demonstrate a track record of producing parts for industries like medical devices or aerospace, where precision is non-negotiable. Ask for case studies or sample parts to verify their ability to maintain dimensional stability and surface finish (Ra < 0.1μm) in mass production.

Quality Management Systems in Precision Micro Injection Molding

Quality management is non-negotiable in precision micro injection molding, where even minor defects can render a part useless. A reputable supplier should hold certifications like ISO 9001, ISO 13485 (for medical), or AS9100 (for aerospace), which validate their commitment to strict quality protocols. We recommend examining their in-process inspection methods, such as in-situ metrology tools (confocal microscopy, white-light interferometry) that measure parts immediately after molding. Look for suppliers with statistical process control (SPC) systems that monitor Cpk values (aiming for >1.67) to ensure consistent quality. Traceability is also critical: a reliable supplier should document every step, from material lot numbers to process parameters, allowing you to trace any issues back to their source. Request details on their scrap rates—ideally below 1% for high-tolerance parts—and their corrective action procedures for non-conforming items.

Material Expertise and Supply Chain in Precision Micro Injection Molding

Material selection directly impacts the performance of precision micro injection molded parts, so choosing a supplier with deep material expertise is essential. A strong supplier should guide you in selecting polymers or composites that balance flow properties (critical for filling micro-cavities) with mechanical requirements (strength, heat resistance). They should also demonstrate strict material handling practices, such as pre-drying resins to <0.005% moisture content to prevent defects. Evaluate their supply chain resilience: do they have relationships with trusted material suppliers to ensure consistent quality? Can they source specialty materials, like bio-based polymers or conductive composites, for unique applications? A supplier with robust material management will also test each batch for consistency, providing certificates of analysis to confirm compliance with your specifications.

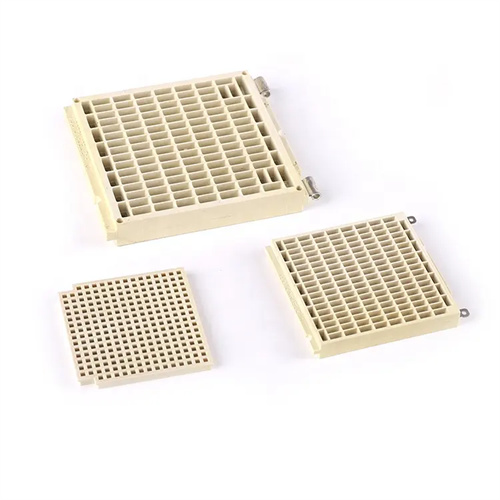

Production Capacity and Scalability in Precision Micro Injection Molding

When choosing a precision micro injection molding supplier, assess their ability to meet your production needs—both now and in the future. Evaluate their production capacity, including the number of micro molding machines, multi-cavity mold capabilities (up to 100+ cavities for tiny parts), and automated handling systems. A supplier with flexible manufacturing cells can quickly adapt to changes in volume, whether you need 1,000 prototype parts or 1 million production units. Scalability is key: ask about their lead times for tooling (ideally 4–6 weeks for micro molds) and production ramp-up. Can they accommodate design changes without significant delays? Look for suppliers using digital twins or rapid prototyping (3D-printed molds) to accelerate time-to-market. A partner with strong project management will also provide clear timelines and communicate proactively about potential bottlenecks.

Cost Structure and Total Value in Precision Micro Injection Molding

While upfront costs are a consideration, focusing solely on price can lead to hidden expenses in precision micro injection molding. A low-cost supplier may cut corners on mold quality or inspection, resulting in higher scrap rates or failed assemblies. Instead, evaluate total value: a reliable supplier will balance quality with efficiency, using multi-cavity molds, automated systems, and optimized processes to reduce per-unit costs. Ask for a detailed cost breakdown, including tooling, material, labor, and inspection. Consider long-term savings: a supplier with tight process control will minimize rework, while one with strong material management will reduce waste. Be wary of suppliers who quote significantly lower prices without explaining their methodology—this often indicates compromises in precision or quality. A transparent supplier will work with you to optimize designs for manufacturability (DFM), reducing costs without sacrificing tolerances.

Technical Support and Collaboration in Precision Micro Injection Molding

Successful partnerships in precision micro injection molding rely on strong technical support and collaboration. A top supplier should engage early in the design phase, offering DFM insights to optimize part geometry for micro molding—for example, suggesting draft angles or wall thicknesses that improve fill and reduce warpage. They should have a team of engineers with expertise in micro-feature design, material science, and process optimization to address challenges like flash or short shots. Communication is critical: look for a supplier who provides regular updates on tooling progress, production metrics, and quality data. Post-delivery support is also important—will they assist with troubleshooting if parts perform differently than expected in your assembly? A collaborative supplier acts as a partner, invested in your success, rather than just a vendor.