High-Volume Injection Molding: Bridging Prototypes and Mass Production

The journey from prototype to 1M+ units demands a seamless transition—and our high-volume injection molding processes are engineered to make this leap feel effortless. We start by collaborating with clients during the prototype phase, not just to refine part designs but to ensure they’re production-ready for high-volume manufacturing. Our team uses 3D printing and CNC machining to create functional prototypes, testing form, fit, and function before finalizing designs. But unlike prototype-focused shops, we simultaneously analyze each design for high-volume feasibility: Can this geometry be molded efficiently? Will the material hold up in mass production? What tooling modifications are needed to scale? By addressing these questions early, we eliminate costly redesigns later. For example, a client’s initial prototype might feature a complex undercut that works for small runs but would slow high-volume production—we suggest a minor tweak that preserves functionality while reducing cycle time by 15%. This proactive approach ensures that when it’s time to scale, the transition to high-volume injection molding is smooth, with no unexpected delays.

High-Volume Injection Molding: Tooling Designed for Scalability

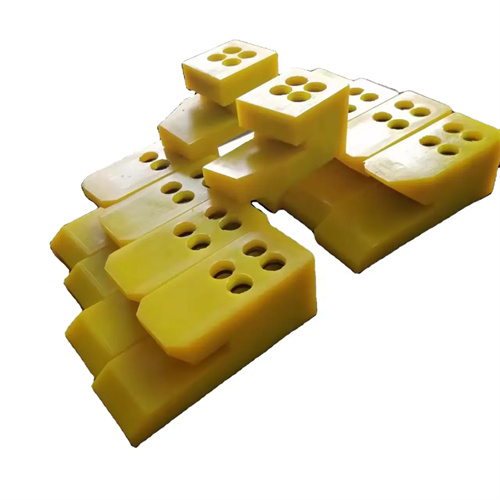

Tooling is the backbone of seamless volume scaling—and our high-volume injection molding tooling is built to grow with your project. For prototypes, we often use aluminum molds that allow for quick adjustments, but we design them with an eye toward the steel production molds that will eventually handle 1M+ units. This means incorporating features like standardized mold bases, cooling channel layouts, and ejection systems that can be replicated in larger, more durable steel tools. We also use modular tooling components that allow for easy upgrades: a prototype mold might start with a single cavity, but its design enables us to add more cavities as production scales, increasing output without overhauling the entire tool. Our tooling engineers work with clients to balance upfront costs with long-term efficiency, ensuring that even the initial prototype tooling investments contribute to a smoother transition to high-volume injection molding. By the time we hit 1M units, the tooling feels like a natural extension of the prototype phase, not a brand new process.

High-Volume Injection Molding: Scaling Processes Without Sacrificing Speed

Scaling from prototypes to 1M+ units requires more than bigger machines—it demands processes that can ramp up efficiently, and our high-volume injection molding operations excel here. We start with small-batch production runs (typically 10,000–50,000 units) using our prototype tooling, validating production parameters like temperature, pressure, and cycle time. These runs serve as a testing ground: we monitor part quality, adjust processes, and train teams before scaling further. As demand grows, we transition to multi-cavity steel molds and dedicate production cells to the project, complete with automated part handling, inspection, and packaging systems. Our production planning software ensures that raw materials, labor, and machine time are allocated in advance, so we can increase output from 10,000 to 100,000 units per month without bottlenecks. For example, when a consumer goods client needed to scale from 50,000 to 500,000 units in 90 days, our process allowed us to add two more cavities to their mold and reconfigure their production cell, hitting the target with room to spare.

High-Volume Injection Molding: Maintaining Quality Across Volume Gaps

One of the biggest challenges in scaling is keeping quality consistent—and our high-volume injection molding processes ensure that a part made at 100 units is identical to one made at 1M units. We implement statistical process control (SPC) from the prototype phase, establishing baseline measurements for critical dimensions, surface finish, and material properties. As production scales, we expand these controls: inline vision systems that check 100% of parts, automated sampling plans that test tensile strength and impact resistance, and real-time monitoring of mold temperatures and pressures. We also use the same raw material specifications across all production phases, avoiding the temptation to switch to cheaper materials when volumes increase. For a medical device client, this meant maintaining the same biocompatible resin from prototype to 2M units, with every batch tested for purity and consistency. By embedding quality checks into every step of the scaling process, we ensure that high-volume injection molding delivers parts that meet the same standards as the prototypes—no compromises, no surprises.

High-Volume Injection Molding: Collaborating for Predictable Scaling

Seamless scaling is a team effort—and we partner with clients to create a roadmap from prototype to 1M+ units that’s both ambitious and achievable. Our project managers work with clients to define volume milestones, timelines, and budget targets, then break down the process into manageable phases. During the prototype phase, we provide a detailed scaling plan that outlines when tooling upgrades will be needed, how production cells will be configured, and what workforce adjustments are required. We also offer regular progress reports, sharing data on cycle times, scrap rates, and cost per unit to help clients make informed decisions about ramping up. For example, a automotive supplier client used our scaling projections to align their own assembly schedules, ensuring that our 100,000 units per month matched their production needs exactly. This collaborative approach turns high-volume injection molding from a vendor service into a partnership, where both sides are invested in smooth, predictable growth.

High-Volume Injection Molding: Adapting to Market Demands

Market demands can shift overnight—and our high-volume injection molding processes are flexible enough to scale up, slow down, or pivot as needed. We design our production lines to be modular, so we can quickly reallocate machines, labor, and materials to meet sudden surges in demand. If a client’s product takes off faster than expected, we can add extra shifts, expedite tooling upgrades, or even temporarily run parallel production lines to hit 1M+ units ahead of schedule. Conversely, if demand slows, we can reduce output without idle equipment, thanks to our ability to repurpose production cells for other projects. Our material inventory management system uses real-time demand data to adjust resin orders, ensuring we have enough stock to scale but not so much that capital is tied up in excess inventory. This agility was put to the test when a tech client’s new product went viral—we scaled from 50,000 to 1.2M units in six months, using our high-volume injection molding expertise to meet the demand without sacrificing quality. In the end, seamless scaling isn’t just about hitting numbers—it’s about adapting to whatever the market throws your way.