High-Volume Injection Molding: Certified for Global Compliance

As a global supply chain-ready partner, our high-volume injection molding operations are built on a foundation of rigorous certifications that meet international standards, ensuring seamless integration into global production networks. We hold ISO 9001, ISO 13485 for medical devices, and IATF 16949 for automotive components, with regular audits to maintain compliance across all facilities. These certifications validate our commitment to consistent quality, process control, and risk management—critical for clients operating in regulated industries worldwide. For example, our ISO 13485 certification ensures that high-volume medical part production adheres to strict traceability requirements, from raw material sourcing to final shipment. We also comply with regional standards, such as REACH and RoHS in the EU, and FDA regulations in the U.S., eliminating barriers to market entry for our clients. By aligning high-volume injection molding with global certifications, we provide the reliability that multinational companies demand when building their supply chains.

High-Volume Injection Molding: Logistics Built for Global Reach

High-volume injection molding isn’t just about producing parts—it’s about delivering them where they’re needed, when they’re needed, and our logistics network is engineered for global efficiency. We’ve established strategic partnerships with leading freight forwarders and carriers, enabling door-to-door delivery to 50+ countries with predictable lead times. Our facilities are located near major ports and transportation hubs, reducing transit times for both inbound raw materials and outbound finished goods. For high-volume runs, we use advanced demand planning tools to coordinate production with shipping schedules, ensuring that container loads are optimized to minimize costs. We also offer flexible shipping options, from air freight for urgent orders to ocean freight for cost-effective bulk shipments. For a European automotive client, this meant shipping 500,000 interior components monthly from our U.S. facility to their assembly plant in Germany, with transit times consistently within 14 days. By integrating logistics into high-volume injection molding, we turn production capacity into global supply chain capability.

High-Volume Injection Molding: Multi-Regional Production for Local Agility

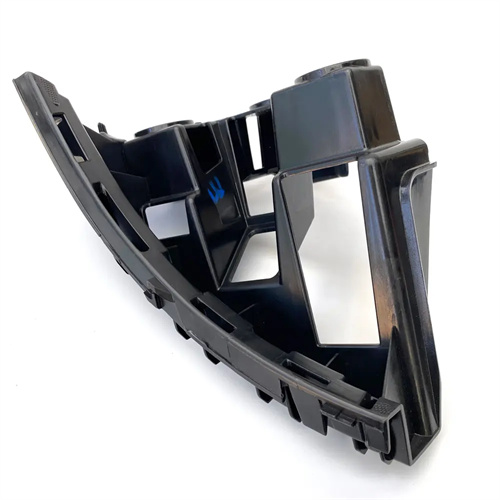

To serve global supply chains effectively, we’ve built a network of high-volume injection molding facilities across key regions, combining global scale with local responsiveness. Our plants in North America, Europe, and Asia each specialize in high-volume production while adapting to regional market needs—whether it’s material preferences, packaging requirements, or regulatory nuances. This multi-regional footprint reduces lead times and transportation costs, as clients can source parts from the facility closest to their assembly operations. For example, a consumer electronics company uses our Asian plant for high-volume production of smartphone cases for the APAC market, while our North American facility supplies the same part (with minor regional adjustments) to their U.S. and Canadian customers. All facilities share standardized processes and quality systems, ensuring that a part made in Germany is identical to one made in Mexico. This balance of global consistency and local agility makes our high-volume injection molding network a cornerstone of our clients’ global supply chains.

High-Volume Injection Molding: Supply Chain Resilience for Uncertainty

Global supply chains face constant disruptions—and our high-volume injection molding operations are designed to maintain continuity, even in challenging conditions. We’ve implemented dual-sourcing strategies for critical raw materials, working with multiple suppliers across different regions to avoid shortages. Our production facilities are equipped with redundant systems, from backup power generators to alternative production lines, ensuring that high-volume runs continue uninterrupted. We also use scenario planning tools to anticipate potential disruptions—whether it’s a port closure, material shortage, or geopolitical event—and develop contingency plans to mitigate risks. During a recent resin shortage, for example, we shifted production of a high-volume automotive part to an alternative material that met specifications, using our material science expertise to maintain quality while keeping the supply chain intact. By building resilience into high-volume injection molding, we provide clients with the stability they need to navigate global uncertainties.

High-Volume Injection Molding: Collaborative Planning for Global Success

Success in global supply chains requires alignment—and we collaborate closely with clients to integrate our high-volume injection molding capabilities into their broader supply chain strategies. Our account managers work with clients’ procurement, production, and logistics teams to develop joint forecasts, ensuring that our production capacity matches their demand. We share real-time data through cloud-based platforms, providing visibility into inventory levels, production progress,and shipping status across our global facilities. For a multinational appliance manufacturer, this collaboration included quarterly planning sessions to align high-volume production of plastic components with their product launch schedules in 12 countries. We also participate in their supplier development programs, sharing best practices for lean manufacturing and sustainability to drive continuous improvement across the supply chain. This collaborative approach turns our high-volume injection molding operations into an extension of our clients’ teams, working together to achieve global supply chain goals.

High-Volume Injection Molding: Sustainability for Global Impact

In today’s global supply chains, sustainability is non-negotiable—and our high-volume injection molding operations are designed to reduce environmental impact while meeting global demand. We’ve set ambitious targets to reduce carbon emissions across our facilities, investing in renewable energy sources like solar panels and optimizing transportation routes to cut fossil fuel use. Our material recycling programs recover and reuse production scrap, with some facilities achieving a 95% recycling rate for high-volume runs. We also work with clients to transition to eco-friendly materials, such as bio-based resins and recycled-content plastics, without compromising part performance. For a global packaging client, this meant switching to a 30% recycled resin for their high-volume food containers, reducing their carbon footprint by 20% while maintaining compliance with global food safety standards. By embedding sustainability into high-volume injection molding, we help clients meet their ESG goals and build supply chains that are not just global, but responsible.