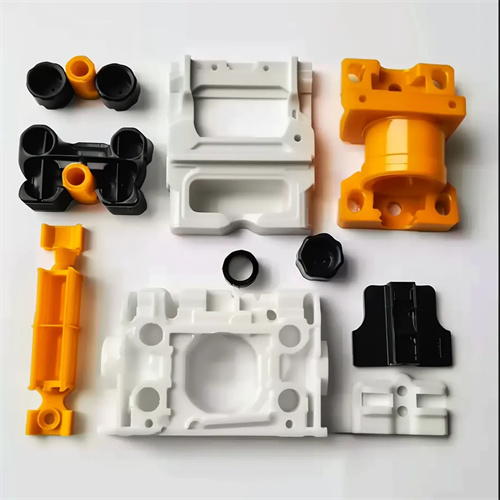

Custom Injection Molding Services: Small Batch Solutions for Testing and Validation

Our custom injection molding services excel in small batch production, providing the flexibility to create 10 to 5,000 parts that let you test market demand, validate designs, or launch limited-edition products without overcommitting resources. We use aluminum tooling for these runs, which is cost-effective and quick to fabricate, allowing us to deliver your first batch in as little as 2–3 weeks. These small batches use production-grade materials, ensuring the parts behave exactly like they will in full-scale manufacturing, so you can assess factors like durability, fit, and customer reception with confidence. Our team works with you to refine details during this phase—whether adjusting a texture for better grip or tweaking a dimension for improved assembly—making it easy to iterate before scaling up. Small batch production also helps you manage cash flow, as you only invest in the quantity you need to validate your product. With our small batch custom injection molding services, you get the flexibility to test, learn, and adapt without the risks of large upfront investments.

Custom Injection Molding Services: Medium Batch Production for Growing Demand

As your product gains traction, our custom injection molding services seamlessly transition to medium batch production, supporting runs of 5,000 to 50,000 parts to meet growing demand. We maintain the same precision and quality as small batches but optimize processes for efficiency, using a mix of aluminum and steel tooling depending on your volume needs. Aluminum molds work well for medium runs up to 30,000 parts, while steel molds are recommended for higher volumes to ensure durability. Our production lines are designed for quick changeovers, so we can adjust to fluctuations in your order size—whether you need a 20% increase to meet a sudden spike in sales or a temporary reduction to align with seasonal demand. We also offer value-added services during medium batch production, such as assembly or packaging, to streamline your supply chain. This flexibility means you can scale production in line with your growth, avoiding excess inventory while ensuring you never run out of stock. With our medium batch custom injection molding services, we grow with your business, step by step.

Custom Injection Molding Services: Mass Production Capabilities for High-Volume Needs

When your product is ready for mass production, our custom injection molding services deliver the scale and efficiency to produce 50,000+ parts with consistent quality and competitive pricing. We use high-performance steel tooling, such as H13 or S7, which can withstand millions of cycles without wear, ensuring long-term reliability and dimensional stability. Our mass production lines feature automated systems—including robotic part removal, in-line inspection, and material handling—to maximize throughput and minimize errors, with the capacity to produce millions of parts monthly. We optimize cycle times by fine-tuning injection parameters and using advanced cooling systems, reducing production time per part while maintaining strict tolerances. Our team also implements lean manufacturing principles, such as just-in-time (JIT) production, to minimize waste and keep costs low. Even at scale, we maintain flexibility: if you need to modify a part design, our engineers work with you to update tooling efficiently, ensuring minimal downtime. With our mass production custom injection molding services, you get the volume you need without sacrificing quality or agility.

Custom Injection Molding Services: Tooling Flexibility to Support All Production Scales

Tooling is the foundation of flexible production, and our custom injection molding services offer a range of tooling solutions to support every scale from small batches to mass production. For small runs, we use aluminum tooling, which is fast to machine and cost-effective, making it ideal for prototyping or limited releases. These molds can be modified quickly if design changes are needed, supporting agile iteration. For medium to high volumes, we transition to steel tooling, with options like pre-hardened P20 steel for 50,000–100,000 parts or heat-treated H13 steel for millions of cycles. We also design modular tooling systems, where inserts or cavities can be swapped out to produce different part variations on the same base mold—perfect for products with multiple SKUs. This modular approach reduces tooling costs and speeds up changeovers, allowing you to produce different versions of a part without investing in entirely new molds. With our flexible tooling options, our custom injection molding services adapt to your production needs, whether you’re making 100 parts or 10 million.

Custom Injection Molding Services: Quality Consistency Across All Production Volumes

Maintaining quality is critical at every production scale, and our custom injection molding services ensure consistent results whether you’re producing 100 parts or 10 million. We implement the same rigorous quality control measures across all batch sizes, starting with material testing to verify polymer properties like melt flow rate and tensile strength. During production, in-line sensors monitor critical parameters—such as pressure, temperature, and part weight—alerting our team to deviations in real time. For small and medium batches, we conduct 100% visual inspections and random sampling with coordinate measuring machines (CMMs) to check dimensional accuracy. In mass production, we use automated vision systems that inspect every part at high speed, ensuring defects are caught before parts leave our facility. We also document quality data for every batch, providing traceability from raw materials to finished products. This commitment to quality means you can trust that a part produced in a small batch will perform identically to one made in mass production. With our custom injection molding services, quality is never compromised, regardless of scale.

Custom Injection Molding Services: Scalable Partnerships for Long-Term Growth

Our custom injection molding services are built on scalable partnerships, designed to adapt to your evolving production needs as your business grows. We start by understanding your long-term goals—whether you plan to expand into new markets, launch product variations, or increase market share—so we can develop a production strategy that scales with you. For startups or small businesses, we focus on flexibility and low upfront costs, using small batch production to help you gain traction. As you grow, we invest in tooling and process optimizations to support medium and mass production, ensuring a seamless transition without disruptions. Our account managers stay in constant communication, regularly reviewing your sales data and market trends to anticipate changes in demand and adjust production plans accordingly. We also offer value-added services like inventory management, helping you balance stock levels as you scale. By acting as a true partner, not just a supplier, our custom injection molding services become an extension of your team, supporting your growth every step of the way—from your first small batch to mass production success.