In the vibrant and rapidly evolving landscape of LED lighting, custom injection molding services have emerged as an indispensable and transformative force. This advanced manufacturing technique empowers us to craft highly specialized, precisely tailored components that not only meet but exceed the diverse and exacting requirements of modern LED lighting products. From enhancing product performance and durability to enabling innovative designs and driving cost – effectiveness, custom injection molding services are at the heart of our efforts to create cutting – edge LED lighting solutions that illuminate the world around us.

1. Unrivaled Design Flexibility with Custom Injection Molding Services

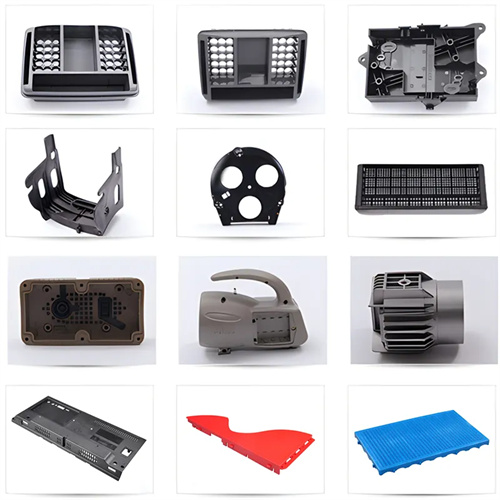

One of the most remarkable advantages of custom injection molding services in the realm of LED lighting is the unparalleled design flexibility it offers. Traditional manufacturing methods often impose significant limitations on our creativity, confining us to simple and standardized shapes. However, custom injection molding shatters these constraints, opening up a world of possibilities for innovative and imaginative designs.

We can bring to life LED fixtures with intricate and complex geometries, such as organic – shaped pendant lights that mimic natural forms or sleek, futuristic – looking recessed ceiling lights with seamless curves. For instance, in a recent project for a high – end commercial building, we utilized custom injection molding to create LED wall sconces with a unique, wave – like design. The ability to mold such complex shapes not only enhanced the aesthetic appeal of the fixtures but also allowed for better integration with the building’s interior architecture.

Moreover, the wide range of materials available for custom injection molding further amplifies our design capabilities. We can choose from a variety of polymers with different properties, such as transparency, flexibility, and heat resistance. Translucent polymers are ideal for creating diffuser covers that evenly distribute light, reducing glare and creating a soft, ambient glow. In contrast, heat – resistant polymers are essential for components that need to withstand the high temperatures generated by LED chips, ensuring the longevity and reliability of the lighting products.

2. Cost – Effective Production through Custom Injection Molding Services

Cost – effectiveness is a crucial factor in any manufacturing process, and custom injection molding services provide us with a significant competitive edge in this regard. While the initial investment in mold creation may seem substantial, it quickly pays off in the long run, especially for large – scale production. Once the mold is developed, the production of multiple identical components becomes highly efficient, driving down the per – unit cost significantly.

According to industry research, in high – volume production runs of over 5,000 units, custom injection molding can reduce the cost per component by up to 40% compared to other manufacturing methods. Additionally, the precise nature of the injection molding process minimizes material waste. The plastic material is injected into the mold cavity with exact precision, using only the amount required for each component. This not only saves on material costs but also aligns with our commitment to sustainable manufacturing practices.

Furthermore, custom injection molding allows us to consolidate multiple parts into a single component. Instead of manufacturing and assembling several individual parts, we can design and mold a single, integrated component that performs the functions of multiple parts. This not only simplifies the production process but also reduces labor costs associated with assembly, further enhancing the cost – effectiveness of our LED lighting products.

3. Superior Quality Assurance with Custom Injection Molding Services

Maintaining consistent and high – quality standards is of utmost importance in the LED lighting industry, and custom injection molding services play a vital role in ensuring product quality. The precision of the injection molding process, combined with advanced design and manufacturing technologies, enables us to produce components with tight tolerances and excellent repeatability.

We utilize state – of – the – art computer – aided design (CAD) and computer – aided manufacturing (CAM) systems to create highly accurate mold designs. These systems allow us to simulate the molding process before production, identifying and resolving potential issues such as material flow problems, air traps, or dimensional inaccuracies. This proactive approach helps us avoid costly mistakes and ensures that the final product meets our stringent quality requirements.

During the production process, we closely monitor and control critical parameters such as temperature, pressure, and injection speed. Automated systems and sensors continuously measure and adjust these parameters to maintain optimal conditions, ensuring that each component is molded to perfection. In – line inspection systems equipped with advanced imaging and measurement technologies are also used to detect any defects or deviations in real – time, allowing us to take immediate corrective action and prevent defective products from reaching the market.

4. Accelerated Time – to – Market with Custom Injection Molding Services

In the fast – paced and highly competitive LED lighting market, time – to – market can be a decisive factor in the success of a product. Custom injection molding services offer us the agility and speed needed to quickly bring new LED lighting products to market. The rapid prototyping capabilities of custom injection molding allow us to transform design concepts into physical prototypes in a relatively short period.

Using 3D printing or CNC machining technologies in conjunction with custom injection molding, we can create functional prototypes that closely resemble the final product. These prototypes can be tested for form, fit, and function, enabling us to make any necessary design modifications before proceeding with mass production. This iterative process significantly reduces the product development cycle, allowing us to respond promptly to market trends and customer demands.

Once the design is finalized, the transition to mass production is seamless. Modern injection molding machines are highly automated and capable of producing large quantities of components in a short time. With the ability to produce hundreds or even thousands of parts per hour, depending on the complexity of the component, we can quickly ramp up production and meet tight deadlines, giving us a competitive advantage in the market.

5. Enhanced Product Performance with Custom Injection Molding Services

Custom injection molding services play a crucial role in enhancing the performance of LED lighting products. By carefully selecting materials with specific properties and optimizing the design of components, we can improve the overall functionality, efficiency, and durability of our LED lighting solutions.

Heat management is a critical aspect of LED lighting, as excessive heat can reduce the lifespan and performance of LED chips. Custom injection molding allows us to create components with integrated heat – sinks or cooling channels that effectively dissipate heat, keeping the LED chips at an optimal operating temperature. In addition, we can use heat – conductive polymers or add fillers to the plastic material to further enhance its thermal conductivity, improving the heat – dissipation capabilities of the components.