In the highly regulated and precision – driven field of medical devices, Two Shot Injection Molding has emerged as an invaluable manufacturing approach for us. This innovative process allows us to create medical products that combine strict safety standards, exceptional functionality, and ergonomic design. By injecting two different materials sequentially, we can integrate complex features such as biocompatible surfaces, precise fluid pathways, and enhanced grip elements into a single device. It has transformed the way we produce medical instruments, enabling us to meet the rigorous requirements of the healthcare industry and improve patient outcomes.

1. Two Shot Injection Molding: Ensuring Biocompatibility and Hygiene in Medical Devices

One of the primary concerns in medical device manufacturing is ensuring biocompatibility and maintaining strict hygiene standards, and Two Shot Injection Molding provides effective solutions. When producing items like syringes, catheters, and implantable devices, we need to use materials that are safe for human contact and resistant to bacterial growth. With Two Shot Injection Molding, we can achieve this by carefully selecting and combining materials. In the first shot, we mold the main structure of the device using a biocompatible plastic, such as polypropylene or polyethylene, which forms the sturdy base. Then, in the second shot, a layer of antibacterial or hydrophilic material is overmolded onto critical surfaces. For example, in the case of a catheter, the outer layer can be made of a hydrophilic material through the second shot, reducing friction during insertion and minimizing the risk of infection. This dual – material design not only ensures the safety of patients but also simplifies the sterilization process, as the seamless construction of two – shot molded devices reduces the likelihood of bacteria harboring in crevices.

2. Two Shot Injection Molding: Achieving Precision in Medical Instrument Design

Precision is of utmost importance in medical instruments, as even the slightest inaccuracy can have significant consequences for patient care. Two Shot Injection Molding enables us to create components with intricate geometries and precise tolerances. In the production of surgical instruments like forceps and scalpels, the first shot can form the rigid, sharp – edged metal – like structure (using metal – filled polymers) that provides the necessary cutting or gripping functionality. The second shot then adds a layer of a softer, biocompatible material to create ergonomic handles. These handles are designed with exact contours to fit the surgeon’s hand, allowing for better control and reducing fatigue during long – duration procedures. Additionally, in the manufacturing of medical sensors and diagnostic devices, Two Shot Injection Molding helps us integrate tiny, precise fluid channels and electrical components. The two – shot process ensures that these delicate features are accurately formed and properly sealed, guaranteeing the reliability and accuracy of the device’s measurements.

3. Two Shot Injection Molding: Enhancing User – Friendliness for Medical Professionals

Medical devices are used by a wide range of healthcare professionals, and user – friendliness can greatly impact their effectiveness. Two Shot Injection Molding allows us to design devices that are intuitive and easy to use. For handheld medical devices such as blood glucose monitors and ultrasound probes, we can use the first shot to create the main body with all the necessary internal components. In the second shot, a soft, rubbery material is added to create a comfortable grip area. This material can also be textured to provide tactile feedback, helping medical professionals to operate the device accurately, even in high – stress situations. Moreover, in the case of disposable medical devices like syringes, Two Shot Injection Molding can be used to create clear, easy – to – read dosage markings. The contrasting colors achieved through the two – shot process make the markings highly visible, reducing the risk of dosage errors and improving patient safety.

4. Two Shot Injection Molding: Strengthening Device Durability and Longevity

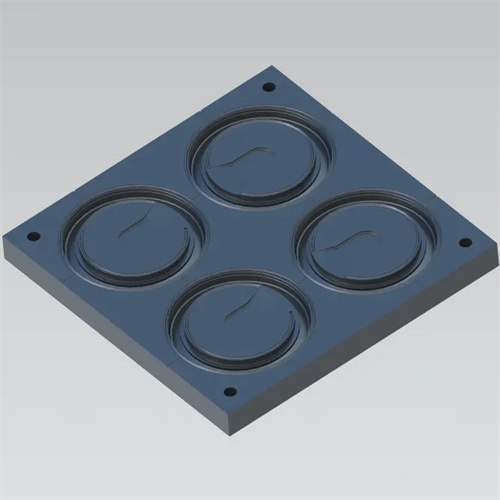

Medical devices often need to withstand repeated use, sterilization cycles, and various environmental conditions, and Two Shot Injection Molding helps us enhance their durability. When manufacturing reusable medical equipment like endoscopes and surgical trays, the first shot can create a tough, impact – resistant outer shell using a high – performance plastic. The second shot then adds a layer of a scratch – resistant and chemical – resistant material. This additional layer protects the device from damage during handling, cleaning, and sterilization processes. For example, in the case of an endoscope housing, the two – shot molded design ensures that the device remains functional and reliable even after numerous autoclaving cycles. The combination of materials also helps to prevent the degradation of the device over time, reducing the need for frequent replacements and ultimately lowering healthcare costs.

5. Two Shot Injection Molding: Pioneering Innovation in Minimally Invasive Devices

The trend towards minimally invasive procedures in modern medicine demands innovative medical devices, and Two Shot Injection Molding is at the forefront of this development. We can use this process to create complex, multi – functional components for minimally invasive devices. For instance, in the production of stents, the first shot can form the expandable metal – alloy – based structure (using appropriate metal – polymer composites). The second shot then adds a layer of a drug – eluting or bioresorbable material. This allows the stent to not only provide structural support to blood vessels but also release medication over time to prevent restenosis or gradually dissolve after fulfilling its function. Additionally, in the manufacturing of micro – catheters for targeted drug delivery, Two Shot Injection Molding enables us to integrate multiple lumens and specialized tip designs in a single, slender device. These advancements in device design made possible by Two Shot Injection Molding are revolutionizing minimally invasive procedures, offering patients less invasive treatment options with faster recovery times.