In the dynamic realm of household appliances, injection molding parts have emerged as indispensable elements, significantly influencing the functionality, durability, and aesthetic appeal of our products. From forming the sturdy exteriors of refrigerators to crafting the intricate components of washing machines, these parts play a crucial role in every aspect of appliance manufacturing. Injection molding parts not only offer us the flexibility to create customized and high – quality components but also ensure cost – effective production and seamless integration, enabling us to meet the diverse and evolving needs of consumers. Let’s explore how injection molding parts are shaping the landscape of household appliances.

1. Sturdy Structural Foundation with Injection Molding Parts

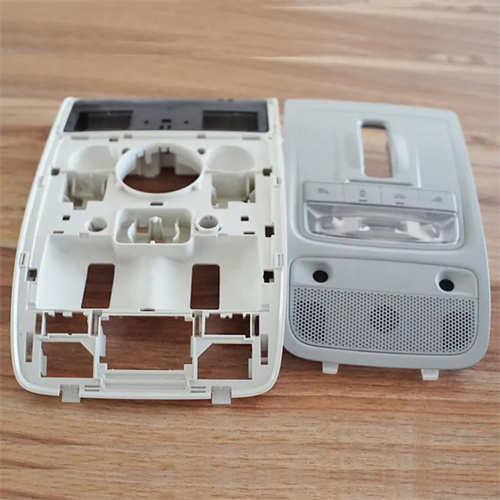

Injection molding parts provide a sturdy structural foundation for household appliances, ensuring their long – term durability and reliability. We utilize a variety of robust materials, such as engineering plastics reinforced with glass fibers and high – impact polymers, to manufacture injection – molded frames, panels, and housings. For refrigerators, injection – molded plastic frames made from glass – fiber – reinforced polypropylene (PP) offer excellent strength and dimensional stability, supporting the weight of the internal components and providing a solid structure for the entire appliance. The precise molding process allows for the creation of parts with complex geometries, including built – in channels for electrical wiring and refrigerant tubing, ensuring a seamless integration of various components.

In washing machines, injection – molded plastic tubs made from high – strength ABS (Acrylonitrile Butadiene Styrene) withstand the high – speed rotations and mechanical stresses during the washing cycle. These tubs are designed with smooth internal surfaces to prevent damage to clothes and are resistant to chemical detergents, ensuring a long service life. The ability to produce parts with consistent wall thickness and precise dimensions through injection molding guarantees the structural integrity of household appliances, reducing the risk of deformation or breakage over time.

2. Cost – efficient Manufacturing Processes with Injection Molding Parts

Cost – efficiency is a significant advantage of injection molding parts in the production of household appliances. Although the initial investment in mold development can be substantial, the long – term benefits in terms of cost savings are remarkable. Once the mold is created, injection molding enables us to produce a large number of identical parts at a rapid pace. For commonly used components like plastic knobs, handles, and covers, a single mold with multiple cavities can produce hundreds of parts per hour. For example, a mold with 32 cavities for manufacturing plastic knobs for kitchen appliances can generate over 1,600 knobs in an hour when operated on a high – performance injection molding machine.

As the production volume increases, economies of scale come into play, driving down the cost per part significantly. Injection molding also minimizes material waste, as the precise injection process ensures that only the required amount of plastic is used, and any excess material can often be recycled and reused. Advanced molding techniques, such as multi – cavity molds and hot runner systems, further enhance production efficiency, reducing both production time and costs. These cost – saving measures allow us to offer high – quality household appliances at competitive prices, making them accessible to a wider range of consumers.

3. Functional Innovation Facilitated by Injection Molding Parts

Injection molding parts open the door to functional innovation in household appliances, enabling us to develop products with enhanced usability and performance. We can design and manufacture parts with a wide range of integrated features to meet specific user needs. For example, in modern dishwashers, injection – molded spray arms with precisely angled nozzles are designed to ensure optimal water distribution, providing a more thorough and efficient cleaning performance. These spray arms are made from corrosion – resistant plastics that can withstand the high – temperature and high – pressure environment inside the dishwasher.

In vacuum cleaners, injection – molded dust canisters with quick – release mechanisms and built – in filters make it easy for users to empty and maintain the appliance. We can also create injection – molded parts with integrated sensors and control interfaces, such as touch – sensitive panels for ovens or humidity – sensing components for dehumidifiers. These functional enhancements not only improve the performance of household appliances but also enhance the user experience, making our products more convenient and user – friendly.

4. Aesthetically Pleasing Designs with Injection Molding Parts

Injection molding parts offer us the flexibility to create aesthetically pleasing designs for household appliances, enhancing their visual appeal and complementing various interior styles. Using computer – aided design (CAD) and computer – aided manufacturing (CAM) technologies, we can bring creative and unique design concepts to life. For example, in the design of microwave ovens, injection – molded plastic doors with sleek curves and glossy finishes can add a touch of elegance to the kitchen. We can incorporate different colors, textures, and patterns during the injection molding process to create appliances that match the aesthetic preferences of consumers.

In addition, injection – molded parts can be used to create decorative elements, such as embossed logos or decorative trims, that enhance the brand identity of our products. For instance, a high – end refrigerator may feature injection – molded handles with a metallic – finish coating, giving the appliance a luxurious look. The ability to customize the aesthetic aspects of injection – molded parts allows us to differentiate our products in the market and attract consumers with visually appealing designs.

5. Sustainable Production Practices with Injection Molding Parts

Injection molding parts play a crucial role in our sustainable production practices for household appliances. We are increasingly using recycled plastics and bio – based polymers to manufacture injection – molded parts, reducing our environmental impact. Many of our injection – molded components for household appliances are now made from post – consumer recycled (PCR) plastics, giving waste plastic a new purpose and reducing the demand for virgin materials.

Injection molding also allows us to optimize part designs for material efficiency, creating lightweight parts without sacrificing strength and functionality. Lightweight injection – molded parts not only save on raw materials but also reduce energy consumption during transportation and the operation of the appliances. Additionally, the recyclability of injection – molded plastic parts makes it easier to close the loop in the recycling process. By designing parts to be easily disassembled and recycled at the end of the product’s life cycle, we contribute to a more circular and sustainable manufacturing ecosystem in the household appliance industry.