In the ever – advancing construction industry, where innovation, precision, and sustainability are key drivers, Precision Micro Injection Molding has emerged as a transformative technology. It empowers us to manufacture components that not only enhance the structural integrity and functionality of buildings but also contribute to their aesthetic appeal. From creating intricate micro – components for smart building systems to producing durable seals for energy – efficient envelopes, this technology offers solutions that meet the complex demands of modern construction. Precision Micro Injection Molding combines the benefits of high – accuracy production, design flexibility, and cost – effectiveness, enabling us to push the boundaries of what is possible in the construction field. Let’s explore how this technology is revolutionizing the way we build.

1. Micro – scale Structural Reinforcements with Precision Micro Injection Molding

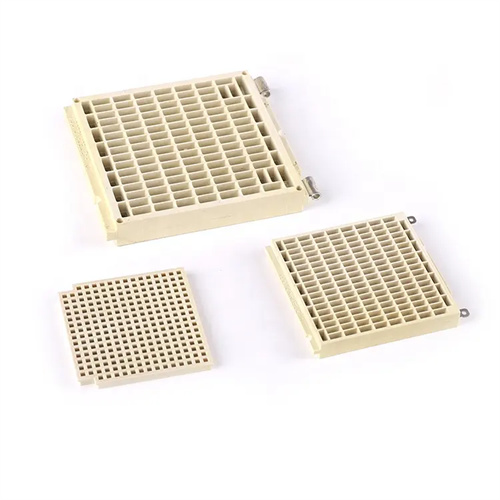

Precision Micro Injection Molding plays a crucial role in the production of micro – scale structural reinforcements for buildings. In the construction of high – rise structures and large – span buildings, we utilize this technology to create tiny yet robust connectors, brackets, and fasteners. These micro – components are designed to reinforce critical joints and connections, enhancing the overall structural stability of the building. For example, in the assembly of steel – framed structures, precision – molded plastic connectors can be used to secure smaller structural elements, providing additional support and reducing the risk of movement or failure.

The high precision of the molding process ensures that each micro – reinforcement has consistent dimensions and mechanical properties, meeting the strict engineering requirements of the construction project. Moreover, the ability to customize the design of these components allows us to tailor them to the specific needs of different structures, optimizing their performance and durability. By incorporating micro – scale structural reinforcements made through Precision Micro Injection Molding, we can build stronger, more resilient buildings that can withstand the test of time and various environmental challenges.

2. Smart Building Integration with Precision Micro Injection Molding

As the construction industry moves towards smart building solutions, Precision Micro Injection Molding enables us to integrate advanced technologies seamlessly. We use this technology to produce micro – sized sensors, actuators, and enclosures for building automation systems. These components are essential for monitoring and controlling various aspects of a building, such as temperature, lighting, and security. For instance, in a smart building, precision – molded sensor housings can be discreetly integrated into the walls or ceilings, providing accurate data on environmental conditions without compromising the building’s aesthetic.

The precision and miniaturization capabilities of the molding process allow for the creation of components that are both highly functional and space – efficient. Additionally, we can design these components to be easily connectable and interoperable, facilitating the integration of different smart systems within a building. By leveraging Precision Micro Injection Molding for smart building integration, we can create more intelligent, energy – efficient, and comfortable living and working environments.

3. Energy – efficient Sealing Components via Precision Micro Injection Molding

Energy efficiency is a top priority in modern construction, and Precision Micro Injection Molding helps us achieve this goal through the production of high – performance sealing components. We manufacture micro – sized gaskets, weatherstripping, and seals with exceptional precision for building envelopes. These components are designed to create airtight and watertight seals around windows, doors, and other openings, preventing heat loss and air infiltration. In cold climates, precision – molded window gaskets can significantly reduce the amount of warm air that escapes from a building, lowering heating costs and improving energy efficiency.

The material properties of the components produced through this technology, such as elasticity and durability, ensure long – lasting performance. The high – precision manufacturing process guarantees consistent quality, ensuring that each seal fits perfectly and provides reliable protection against the elements. By using energy – efficient sealing components made with Precision Micro Injection Molding, we can contribute to reducing a building’s energy consumption and its overall environmental impact.

4. Aesthetically – enhanced Architectural Details with Precision Micro Injection Molding

Precision Micro Injection Molding offers us the opportunity to create aesthetically – enhanced architectural details that add a touch of elegance and uniqueness to buildings. We can produce intricate moldings, decorative panels, and ornamental elements with extreme precision and fine detail. In the design of facades, precision – molded decorative components can be used to create patterns, textures, and motifs that reflect the architectural style and character of the building. For example, in a historic building renovation, we can replicate traditional decorative elements with high accuracy using this technology, preserving the building’s heritage while enhancing its visual appeal.

In contemporary architecture, we can also explore innovative design concepts, using Precision Micro Injection Molding to create unique and eye – catching architectural details. The ability to customize the design and finish of these components allows us to create buildings that stand out in the urban landscape and make a statement. By focusing on aesthetically – enhanced details, we can elevate the overall look and feel of a building, making it more appealing to occupants and passers – by alike.

5. Cost – effective and Sustainable Construction with Precision Micro Injection Molding

Despite its advanced capabilities, Precision Micro Injection Molding offers cost – effective and sustainable solutions for the construction industry. Once the mold is developed, the high – speed injection process allows for mass production of components with relatively short cycle times, reducing production costs. Multi – cavity molds can be used to produce multiple parts simultaneously, further increasing efficiency and lowering the cost per unit.

The precise injection control of the molding process minimizes material waste, as only the required amount of material is used. Additionally, we can use recycled plastics and bio – based polymers in the production process, contributing to a more sustainable construction approach. These materials not only reduce the environmental impact but also offer similar performance characteristics to traditional plastics. By adopting Precision Micro Injection Molding in construction, we can achieve cost savings without compromising on quality while also promoting environmental sustainability.